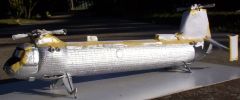

Airfix 1/72 Bristol 192 Belvedere

The Bristol 192 Belvedere is a tandem rotor general purpose helicopter which first flew in preproduction form (XG447) on 5 July 1958 with manual control and wooden rotor blades. Later airccraft had power contol and metal blades. It was developed from the earlier Bristol 173 tandem rotor helicopter. The Belvedere uses two 686 kW (1230 kW emergency) Napier Gazelle Mk.101 turboshaft engines, interconnected so that if any one engine fails, the other engine can power both rotors. A total of 26 Belvederes were built, the first 10 being preproduction, with production aircraft being delivered from 1961. The first preproduction aircraft had anhedral tailplanes with fins, with three aircraft (XG453, XG454 and XG456) having the fins removed. Production aircraft had "double-anhedral" extended tailplanes, of which the preproduction aircraft were subsequently modified to. Production aircraft also had different air inlets while early preproduction aircraft had bare landing gear legs.

Operational Belvederes had the designation HC.1. The Belvedere was operated by two crew and could carry internal payloads of 2720 kg, 2360 kg underslung, 18 troops, 12 stretcher cases with two attendents or up to 30 passengers in search and rescue. The Belvedere were first operated by No.66 Squadron in September 1961 and later by No. 26 and 72 squadrons until 1969, when the aircraft was retired.

The Kit

The Airfix kit is as far as I know, the only plastic kit of the Belvedere. It was first issued in 1959 (making it 50 years old this year!) and represents an early preproduction aircraft with tailplane fins and bare landing legs. Decals are provided for the second preproduction aircraft XG448 in late 1959 (the same as the first release, but with extra stencils) and eighth preproduction aircraft XG454. The kit indicates that the fins are not attached for XG454, but the only photo I could find of one of these finless aircraft shows a much wider tailplane, so this configuration may not be correct. The kit was in continuous production up to 1978, with a short reissue in 1980 and a longer reissue from 1997 to 2001.

|

Type 11 box. |

I first built this kit without paint in the early 1970s. Thanks to the 1997 reissue, I can now have another go. As per kits of this vintage the fuselage is covered in rivets. The part quality was actually quite good with only some minor sink marks, scratches and other imperfections. The only difficult part of the kit is the canopy which is split in two halves. This will result in a visible join line at the front of the canopy. There are also two door options, a normal transport door and a winch door, which can be displayed open or closed. The early Airfix boxart seemed to show the winch door, so I chose that, but in the closed position.

|

Parts laid out |

I of course chose XG448, the same as when I last built the kit.

Assembly

Assembly of the kit was fairly straight forward, the only difficult part being the two canopy pieces. I thought long and hard of how to make a strong smooth join with the seam as least visible as possible. After rejecting superglue as being too visible and clear drying glue as too weak I decided on using carefully applied liquid glue. I first polished the canopy pieces to get a nice clear finish. The pieces were then joined together with Tamiya tape and test fitted against the fuselage to make sure the fit would be OK, which it was. I then removed tape from the top half of the canopy and carefully applied liquid glue to the join with a small brush. Capillery action would draw the glue into the join, minimising the amount of glue in surrounding areas. After that had dried, I repeated the same process to the bottom of the canopy. I then sanded the join with fine wet and dry paper which I then polished to get clear again. Of course, you can still see the join, but I think I achieved my aim of mimimising the visibility of the join line. It could have been much worse!

For the cockpit interior I made it straight out of the box with no added details. Of course, the Airfix pilots were included, ready for takeoff! In order to fit the canopy I had to sand down the sides of pilot's shoes. I left the fuselage sides fully riveted as I could not be bothered sanding everything down and rescribing. In any case, I like the "detail" that rivets give!

|

For the rotor blades, I sealed the bottom of the holes at the base of the blades with plastic rod, sanding down to get a smooth finish. I had to drill the holes a little wider, in order to fit the blades to the rotor hubs. After attaching all the blades in final assembly, I accidently released the model where two of the blades broke off, one for each rotor. The rotor hub rod is only about 1 mm diameter so just using glue will not work, as the weight of the blade will easily break the join. I used a very small drill to drill tiny holes into the hub and blade, joing the hub and blade using a short piece of wire and superglue. I had to prebend the wire first to compensate for the weight of the blade. This gave a strong join. The only problem was that I drilled the holes a bit offset from the centre, so that there a now a bit of a kink where the join is. I applied putty to the join and after drying, sanded the join to minimise the effect of this offset.

For the front wheels the hole diameter was a bit large, so I inserted a piece of platic card and redrilled a smaller hole. For the the bottom air inlets, I cut off the lugs that connect to the bottom of the fuselage. This allows you to see straight though the sides of the air inlets. I also drilled holes in these air intakes into what I believe are drainage holes. The exhaust outlets were also drilled to make them wider.

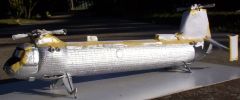

Painting and Decals

As with my previous RAF white and silver schemes, the first step is to get a nice overall finish using grey primer. This is followed with two coats of gloss white on the upper surfaces and after masking and a couple of coats of Klear floor polish, Humbrol polished aluminium H27002 straight from the tin to the lower surfaces. After the decals were applied, a coat of Klear is applied to seal everything in. I really like H27002 as it is so easy to use and gives a very nice finish.

|

|

After masking and painting. |

The decals have a great many additional stencils compared to the first issue, which helps to bring out the model I think.

Conclusions

Another Airfix kit that I wanted to make again. I'm very pleased with how this turned out. Apart from the canopy, the kit was pretty easy to put together. I wonder if we'll ever see a Belvedere from another kit maker, or if this will be the only kit for the next 50 years!

References

Friends of the The Helicopter Museum, "Restoring the Bristol Belvedere XG452," http://www.hmfriends.org.uk/restorbelv.htm.